Resin 3D printers have been popular for a while now, mainly because of their ease of use and a significant drop in price. Stereolithography, the technology behind most resin 3D printing, is often referred to as the “mother of all 3D printing technologies” and is considered one of the most widely used techniques for producing high-quality 3D prints. Many people wonder what exactly a resin 3D printer is and how it works. This article will tell you what is Resin 3D Printer and how does it work.

How Much Are Resin 3D Printers?

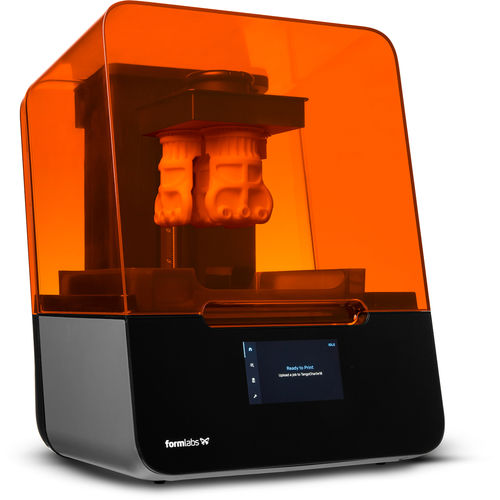

Like the ElegoMars Pro, resin 3D printers start at around $250. Like the Anycubic Photon Mono X, you can get a good mid-range resin 3D printer for $350-800, and like the Formlabs 3, a top-of-the-line professional resin 3D printer can cost upwards of $3000. They are getting cheaper.

Resin 3D printers can be considered simple machines as they do not include many moving parts. This is why resin 3D printers can be purchased at relatively low prices. Most of its components are what we use in our daily life, such as LCD screens.

What Is a Resin 3D Printer?

A resin 3D printer is a machine that holds a barrel of light-sensitive liquid resin and exposes it layer by layer to an ultraviolet LED beam to harden the resin into a plastic 3D model. Known as SLA or stereolithography, the technology can provide 3D printing with extremely fine detail at 0.01mm layer heights.

How Are Resin Printers Constructed?

Typically, resin 3D printers consist of a light source, a build platform (or build plate) where the object is formed, mirrors, and a resin tank. Other tools and features may vary.

Advantages And limitations of Resin 3D Printing?

There are a variety of resin 3D printing methods, and each technology has its own unique elements. It also depends on machine specifications such as light source power, fabrication volume, firmware, and the properties of the photopolymer used.

Advantages of resin printing:

- Very detailed. Photopolymers are loaded into the printer as liquids, so they are easier to mold in complex geometries than molten plastics.

- The surface is smooth. Layer lines still exist in resin printing, but they are so small that they are barely visible in some colors of resin.

- There are many kinds of materials. The market range for resins covers all common applications and needs, and the list is growing rapidly. Each photopolymer resin consists of the working components and additives required for the reaction, such as dyes, vision, and functional supplements.

- The stand doesn’t do much damage to the surface. The resin tank is filled with resin all around, so if there are some lightweight overhangs, they can attach to the part body as it cures.

- High speed. Compared to other prototyping methods, resin printing is faster and modern machines can be very fast.

- Cut costs. For some applications, such as prototyping, custom dental equipment, and jewelry master models, resin printing can save a budget.

- The print is waterproof. Compared to plastic or powder materials, photopolymers are solid and waterproof, they do not absorb moisture from the air, and most can be used in waterproofing applications.

Disadvantages of resin printing:

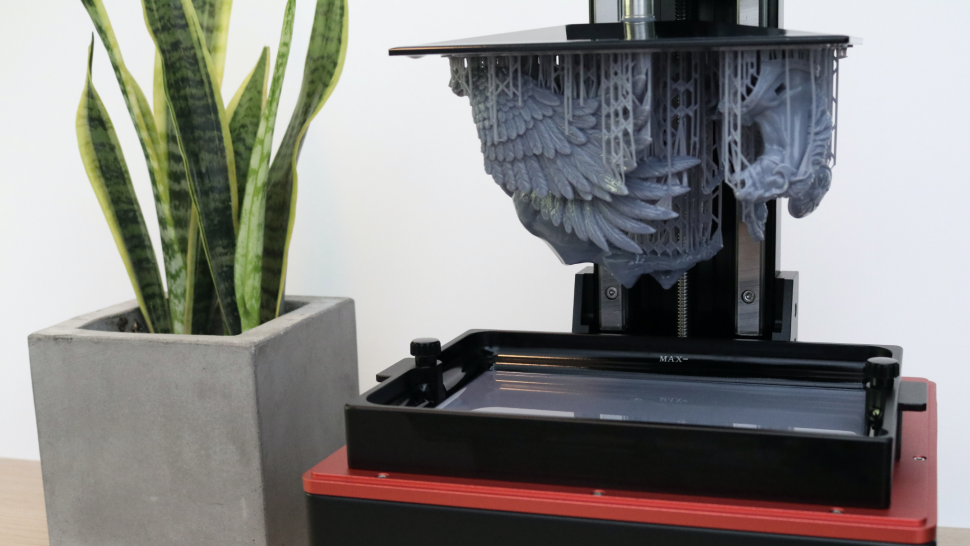

- Many machines have small build volumes. Large-sized objects are quite expensive to manufacture due to the need for industrial-scale devices. It will require filling the entire tank with expensive photopolymers for tall prints, and industrial machines that can be measured in tons, which will increase the cost of the job.

- Design constraints and requirements. Resin printing still has a checklist of things that need to be incorporated into a project while preparing for production. For example, the width and thickness of engraved details should be at least 0.4 mm. Part orientation and mesh quality also affect printing, so some knowledge and experience are required to make a model perfectly.

- Many supporting structures. For the best quality, experts recommend positioning the object so that it doesn’t touch the plate and “flying” at a 45-degree angle. This results in many support structures that are solid after curing and cannot be recycled into the new resin.

- Force postprocessing. We have already mentioned at least 3 necessary post-processing steps required for ready-to-use parts.

After printing, curing continues to run. Polymerization is a tricky thing – after the resin forms an object, some reactions go on inside the part (that’s why post-curing is important). Depending on the part and material, this can lead to shrinkage, cracks, and deformation.

- Cost. We’re not kidding when we say resin printing is more affordable today. It’s worth noting, however, that for technology like SLA, the “reasonable price” is around $3500-4000 for a desktop and $100-200 per liter of resin. For industrial-grade machines, the price may be between $80,000-$250,000 each.

- Tricky solution. An interesting fact about resin printing is that the resolution parameter (accuracy/quality) depends on several factors such as resin type, part orientation, firmware, etc.

What Defines Resin 3D Printing?

- They use the principle of photopolymerization to create objects;

- They operate from code (or machines create code directly from uploaded digital models);

- As a material, they use UV or sunlight resins (photopolymers);

- Materials are stored in vats (tanks/resin tanks).

Photopolymerization is a chemical reaction in which a liquid material changes its properties when exposed to light (UV, laser, etc.). The scientific term for this liquid is photopolymer or light-activated resin, and in 3D printing, they are simply called resins.

There are different types of photopolymerization reactions and results, but the one used for 3D printing is curing. Liquid resins basically become solids under the appropriate wave of light. The light sources can be different, eg lasers, projectors, and LCD panes, which define the type of technology.

How Do Resin Printers Form An Object?

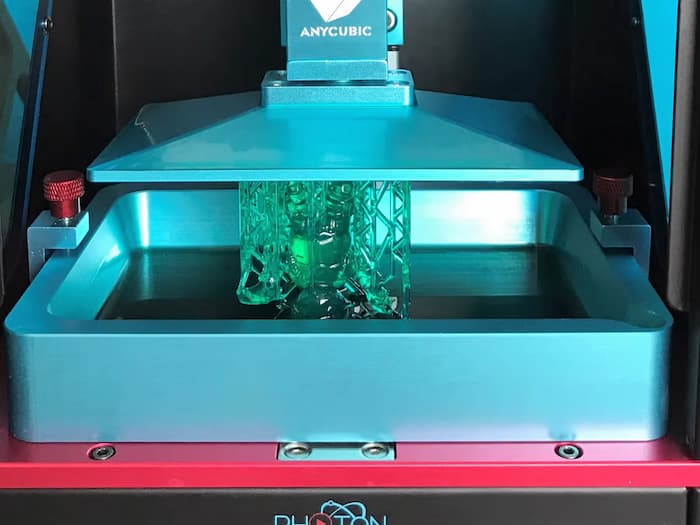

Resin 3D printers can form objects normally or upside down, depending on where the part is located within the machine and whether the build platform is lowered or raised. The inverted orientation is more common on desktops because it is easier to handle and manufacture without loss of quality. The key factors for inverted resin printers are print adhesion and support structure to prevent parts from falling out.

How Does Resin 3D Printing Work?

- Resin tanks are filled with resin material manually or automatically. If specialists fill resin by hand, they should be careful to avoid skin contact, as some resins can be toxic.

- The machine moves the build platform down (or up) to form a thin layer of resin on the build plate.

- A light source draws a single-layer pattern in the resin, allowing it to cure.

- The platform moves to allow the uncured (non-solid) resin to pass through and form a new thin layer over the board.

- If a unit is equipped with rollers, it will pass through the building area to ensure the perfect placement of the resin.

- Repeat these steps until the entire object is formed. After the process is complete, the object is removed from the machine for post-processing.

Types of Resin 3D Printing

Resin 3D printing is a technique in which liquid resin is stored in a container rather than injected through a nozzle. The main terms or types of resin 3D printing include stereolithography (SLA), digital light processing, and liquid crystal display (LCD) or mask stereolithography (MSLA).

SLA

SLA stands for Stereolithography, SLA resin 3D printers work with the help of a UV laser applied to the surface of a photopolymer container (mainly called a resin barrel)

Light is applied in a specific pattern to form the desired shape.

The SLA 3D printer includes various components such as a building platform, resin barrel, light source, elevator, and a pair of galvanometers.

The main purpose of the lift is to increase or decrease the height of the building platform in order to form layers during the printing process. The galvanometer is a pair of movable mirrors that are used to align the laser beam.

Since the resin tank contains uncured resin, it hardens in layers under the influence of UV light and begins to form a three-dimensional model. Resin 3D printers print layer by layer, repeating the process until a fully 3D printed model of the object is complete.

DLP

The digital light processing technology is almost similar to SLA, but instead of lasers, it uses a digital projection surface as the light source.

While using SLA technology to print only one dot at a time, DLP resin 3D printing works by printing one complete layer at a time. This is why DLP resin 3D printing is so much faster than SLA.

They are also considered very reliable as it is not a complex system with no moving parts.

A DMD (Digital Micromirror Device) is a device used to control the precise application position of the projection in a resin 3D printer.

DMDs consist of hundreds to millions of micromirrors that project light at different points and print layered patterns in a better way while integrating the entire layer.

The image of the layer is mainly composed of pixels, as the digital display is the starting point for any layer formed by the DLP 3D printer. In 3D printing, the dots exist in the form of prisms that can be seen from all three angles.

After printing one layer, raise the platform to a specific height in order to print the next layer of the model.

The main advantage of 3D printing with DLP resin is smoother and faster printing. One thing to note here is that the increase in the print area significantly reduces the processing quality.

MSLA/LCD

DLP and SLA can be distinguished from each other, but you may get confused when discovering the difference between DLP and MSLA or LCD (Liquid Crystal Display).

It is known that DLP 3D printing requires additional micromirror devices to transmit light from the projector, but such devices are not required when printing with LCD 3D printers.

The UV beam or light comes directly from the LEDs and shines through the LCD screen. Since this LCD screen is used as a mask, the LCD technology is also widely known as MSLA (Mask SLA).

Since the invention of this MSLA/LCD technology, resin 3D printing has become more popular and more accessible to ordinary people.

This is because individual or add-on components for LCD 3D printing are relatively inexpensive. Keep in mind that LCD 3D printers have a slightly shorter lifespan than DLP chipsets and generally require more maintenance.

Despite this drawback, LCD/MSLA 3D printing is popular due to its smoother surface and relatively fast printing speed. Pixel distortion is an important factor in resin 3D printing, much lower than DLP resin 3D printing.

The actual light from LCD screens is known to be harmful to the organic compounds in them, which means you have to change them based on usage time and performance.

Final Words

Resin 3D printing is an umbrella term for a family of additive manufacturing techniques that solidify liquid photopolymers layer by layer into a solid.

Resin printing is not the official name of the whole group, but since these machines use resin materials, it is a simpler way to describe them. Alternatively, you might come across terms like stereolithography or VAT polymerization printing.